We invite to participate in tender proceedings

in regard to the project:

"Innovative technology for the production

of steamed dough"

Beneficiary

BRZEŚĆ SIPA SPÓŁKA JAWNA

implements the project

“Design and implementation of a new product pre-packaged shortcakes”.

under the Intelligent Development Operational Programme 2014-2020, Sub-measure 2.3.5.

The project aims to increase the company’s competitiveness and innovativeness on the Polish and international markets. These activities enable the introduction of a new product to the company’s offer – pre-packaged shortcakes with high export potential.

The project will result in the expansion of product markets, company growth and increased sales revenue.

Project value: PLN 2,136,510.00

European Funds contribution: PLN 778,950.00

Beneficiary

BRZEŚĆ SIPA SPÓŁKA JAWNA

implements the project entitled:

“Promotion of Crispico Little Snacks brand on international markets

” within the framework of the Operational Programme Intelligent Development 2014 – 2020, Sub-measure 3.

The aim of the project implemented within the framework of 3.3.3 Go to Brand is to promote the Crispico Little Snacks brand through participation in international trade fairs as an exhibitor, including non-EU prospective markets and organisation of an outbound economic mission.

The implementation of the project will contribute to the strengthening of the Applicant’s product brand and increase competitiveness in the international arena.

Project value: PLN 352,585.05

European Funds contribution: PLN 211,551.01

The company Brześć Sipa Spółka Jawna, based in Brześć Kujawski at 19 Konarskiego Street, is pleased to inform you that with the help of EU funds it is implementing the project named:

“Innovative technology for the production of steamed dough”.

under the Intelligent Development Operational Programme 2014 – 2020,

Line of action: Support for Business Innovation

Measure: 3.2 Support for the implementation of R&D results

Sub-measure: 3.2.2 Credit for technological innovation

The project will make it possible to realise the objective by implementing results of independently conducted research and development works concluded with the Research Report. It will allow for diversification of the currently conducted activity by commencing production and introducing a new product to the Company’s range – an eclair-shaped steamed pastry. The beneficiary will also expand its current range of steamed pastry products. The effect of the above-mentioned R&D work is the creation of new own production technology for steamed pastries.

The project will result in the construction of a warehouse building with the necessary infrastructure and equipment, the purchase of fixed assets and the following:

– increasing employment in the company,

– increase in sales revenue,

– reducing energy consumption,

– reducing gas consumption,

The implementation of the project will allow the Beneficiary to become a specialised producer of all steamed dough products.

Project value: PLN 28,000,000.00

European Funds contribution: PLN 12,600,000.00

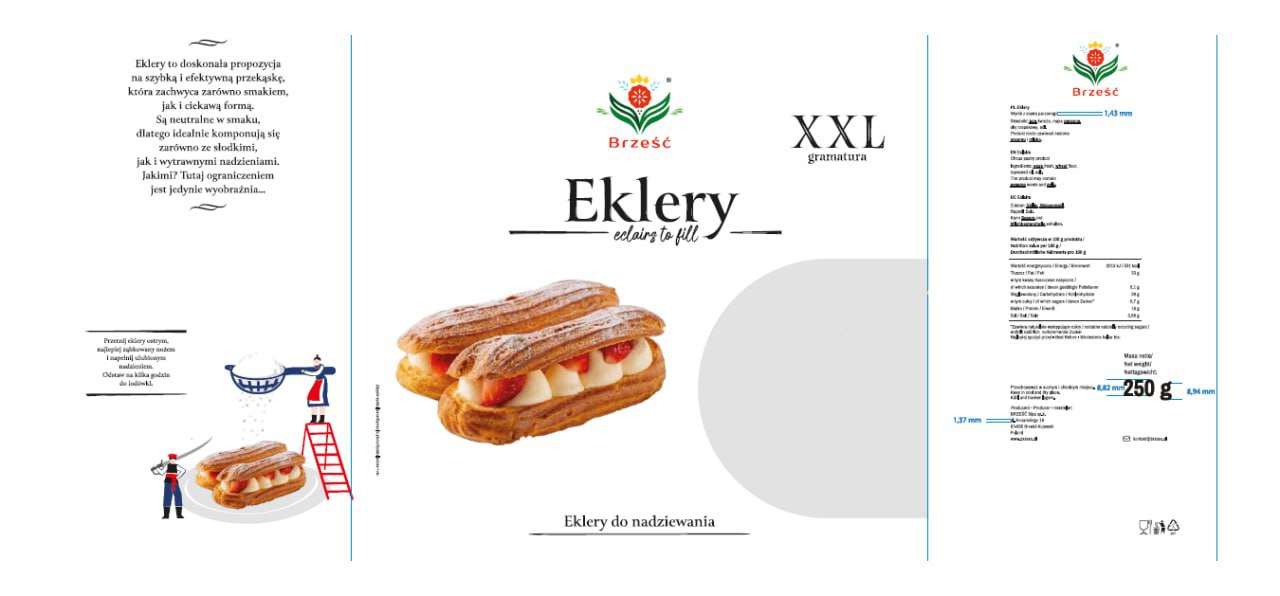

Product information

The body of the cookie is made of choux pastry in the shape of an eclair

Product information based on the research report “Innovative technology for the production of choux pastry” – work carried out from January 2020 to October 2020 and based on the implemented innovative technology for the production of choux pastry.

Research works

The BRZEŚĆ Sipa spółka komandytowa company started conducting research work from January 2020 to October 2020. A team consisting of company employees was established to conduct R&D work. As a result of the research and development work, a product was created called “Eclair-shaped choux pastry cookie body” and improved choux pastry cookie bodies and choux pastry products were created.

“Eclair-shaped choux pastry body” is a product with features and functionalities not available in products currently offered nationwide. This product has innovative features from the point of view of the confectionery industry, it is dried to a level of 2-3%, which allows the shelf life to be extended to several months. The product currently available on the market has a humidity of 15-20% and its shelf life is only a few days.

Confectioners receiving our innovative product will be able to stuff it with all kinds of fillings of their choice, e.g. sweet or savory, thus saving, among others, time, energy, gas and raw materials.

Implementation of innovative technology for the production of choux pastry

On December 15, 2023, devices and machines purchased under the project co-financed by the European Union (Bank Gospodarstwa Krajowego), measure 3.2.2 Operational Program Smart Growth 2014-2020, such as:

Baking line

Beater

Dryer

Flour silo

Oil tank

Internalization system

Automatic and dense pallet storage system

An innovative technology for the production of choux pastry has been implemented

Line building process (baking line)

Line building process (beater)

Flour silo, oil tank

Inertization (oxygen reduction) system for warehouse space for an automatic high-bay warehouse

The purpose of the oxygen reduction system is to provide fire protection to the facility by preventing fire from occurring.

The goal is achieved by reducing and maintaining the oxygen content at an appropriate, safe level, usually <15%, at which the material will not ignite.

Automatic and dense pallet storage system – video

RESULT OF THE IMPLEMENTED TECHNOLOGY

Changes in existing technology allowed for shortening the dough preparation time.

Within 24 hours, using the new technology for the production of choux pastry, we managed to prepare and bake a larger amount of dough than before.

The dough preparation system is programmed so that the given amount of raw materials is accurately measured or weighed and fed to the mixer at the appropriate time and order. The shape and weight of the raw dough are determined by a properly programmed dosing system installed on the oven.

Appropriate oven settings in terms of temperatures in individual sections and appropriate evaporation resulted in a repeatable product, and drying in a dryer resulted in a product that is currently not available on the market.

Indicators such as: reducing the consumption of energy and/or gas used in the production process will be monitored throughout 2024 and their achievement will be sent to BGK in accordance with the provisions of the co-financing agreement and the annex to the co-financing agreement.

As a result of innovative technology for the production of choux pastry, we have obtained products with a shape appropriate to the given product

and size, the products have a characteristic rough surface and internal porosity, light brown color. The products gained the right taste and the smell is repeatable in each batch.

The body of the eclair-shaped choux pastry cookie, when cut, has large air chambers, typical of choux pastry. It is characterized by appropriate volume, convex, elongated shape, equal across the entire width, narrow.

The consistency of the product is brittle and crunchy. Characteristic taste and smell, specific to a given product, ensuring suitability for consumption, without the addition of preservatives.

The product has a moisture content of 2-3%, which indicates the possibility of extending the shelf life.

The use of radio waves allowed the shelf life to be extended without the need to use preservatives – clean label

Extension of shelf life

Eclair-shaped choux pastry bodies offered in confectionery shops after baking and cooling before filling with e.g. creams, whipped cream, have humidity in the range of 15-20%. – therefore their usefulness for consumption is several days.

In the new developed technology – Choux pastry dough body with shape eclair (without filling) is dried to the level of 2%-3%. Product humidity – 2-3% makes the product stable at an angle microbiological, it does not get moldy, and neither do its organoleptic parameters will change. The product is useful for consumption for up to 180 days.

Packaging design

Packaging for the manufactured Eklers has been designed:

unit packaging: BOPP foil with print

The company Brześć Sipa Spółka Komandytowa with its registered office in Brześć Kujawski at ul. Konarskiego 19 informs that on December 2-09, 2022. participated in an economic mission to the United States organized by the Kuyavian-Pomeranian Voivodeship as part of the project:

“Expressway – promotion of investment areas”

co-financed by the European Regional Fund under the Regional Operational Program

Kuyavian-Pomeranian Voivodeship for 2014-2020,

Priority Axis 1: Strengthening the innovation and competitiveness of the region’s economy

Action: 1.5 Developing and implementing new business models for MŚP

Sub-measure: 1.5.2 Support for the internationalization of enterprises.